Calculate the Best Fire Pump Engine for Your Facility’s Pump Room

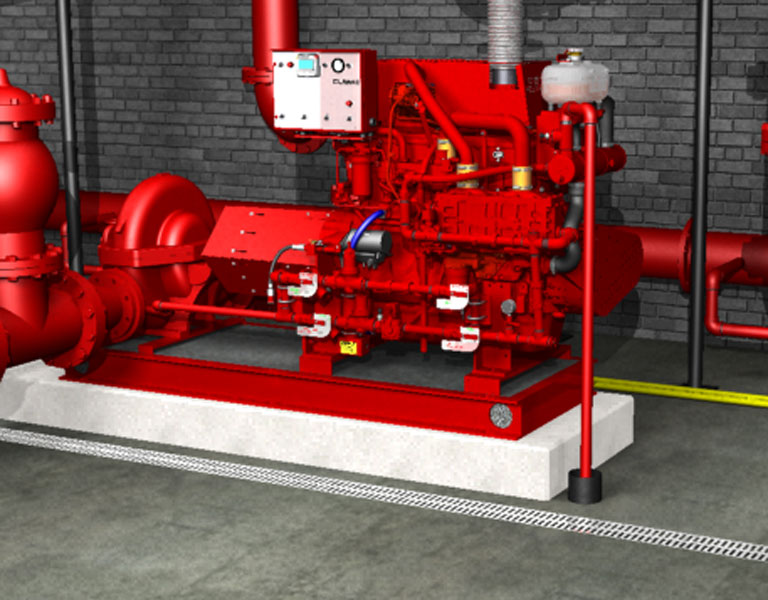

The key to an optimal fire protection sprinkler system is a fire pump that provides consistent flow and pressure to all sprinkler heads in your facility. You need to choose the right fire pump engine for your pump room to ensure your facility’s safety.

Several factors will influence how you select a fire pump engine, including engine de-rate speed, ventilation sizing, cooling loop sizing and more.

PLD-D/PLD-S

See how Clarke can monitor and adjust variable system pressure based on the demand on the fire pump.

Navigate to Each Unique Calculator

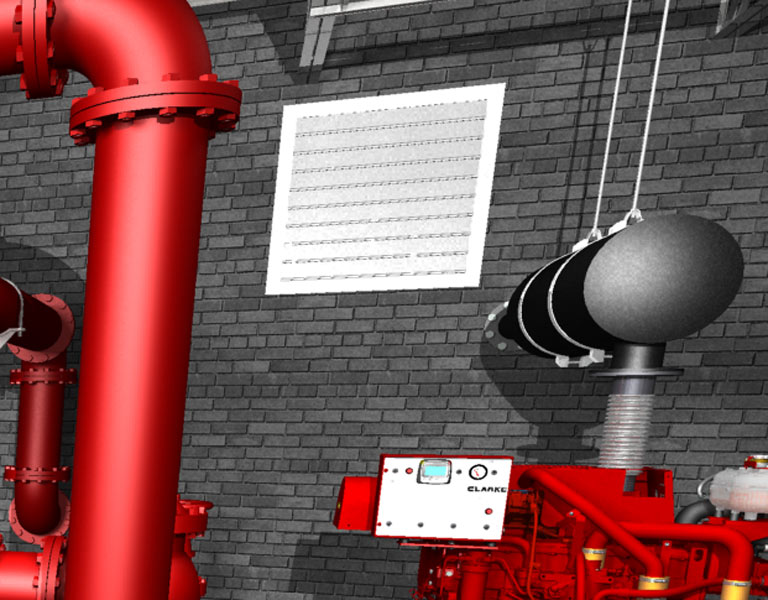

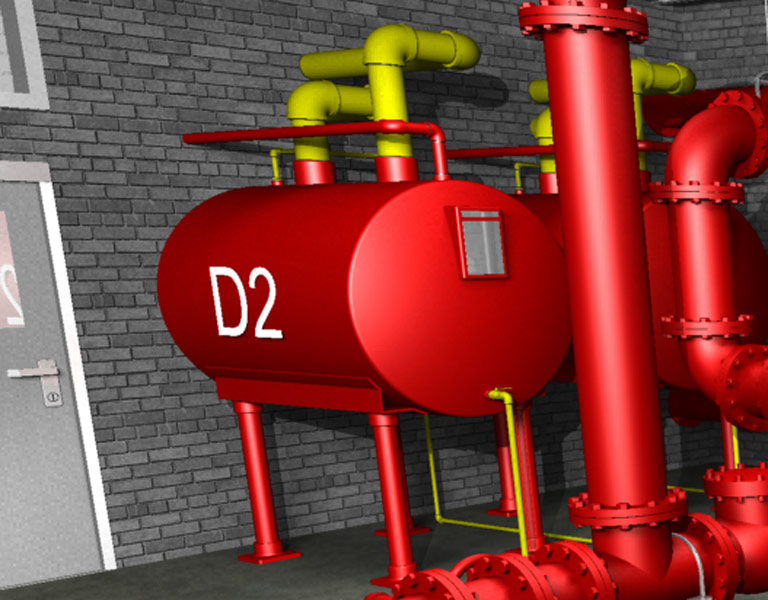

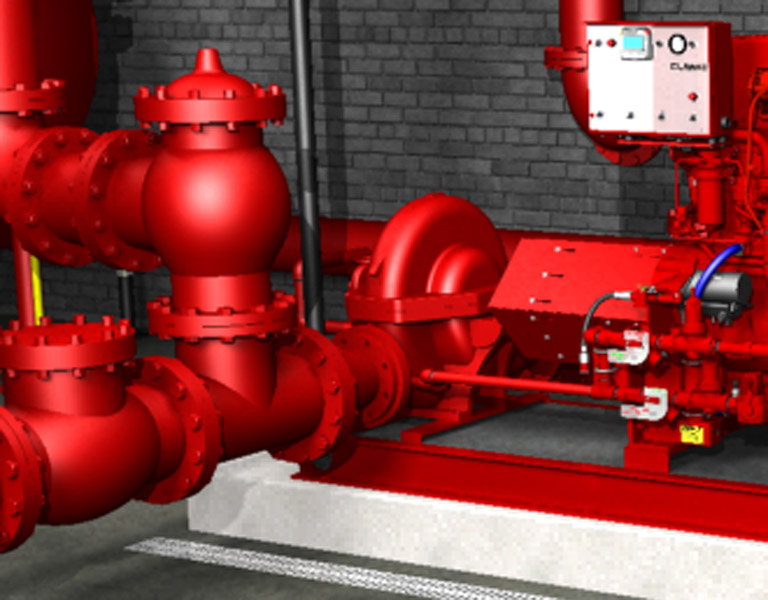

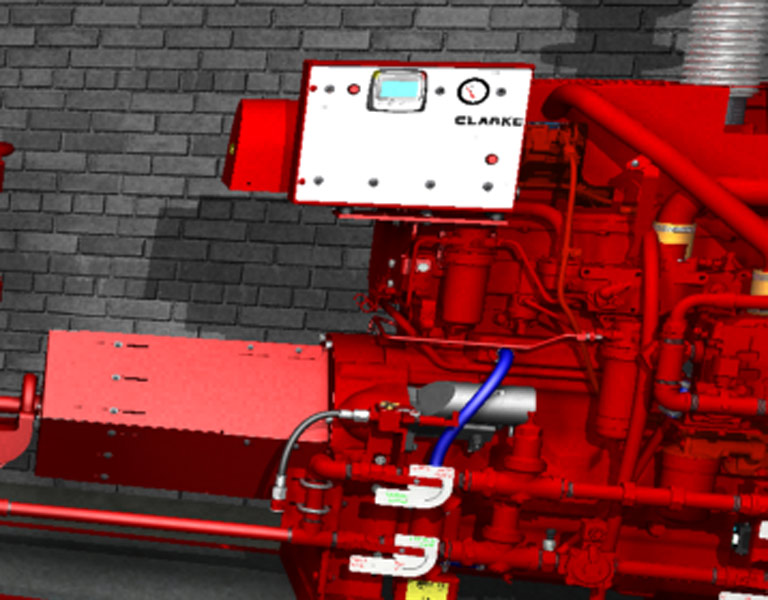

Use the below graphic to learn more about the distinct components of and factors that affect a Clarke fire pump engine. Hover over the icons to reveal descriptions and links to individual component pages.

PLD-D / PLD-S

See how Clarke can monitor and adjust variable system pressure based on the demand on the fire pump.

Verify PLD Suction

Factors to Consider When Selecting a Diesel Fire Pump Engine

Read on for descriptions of fire pump and fire pump room factors to determine which engine model is best for you:

- Engine Selection – Specific conditions to consider including installation location, altitude, pump max power, engine/pump speed, and other de-rate conditions.

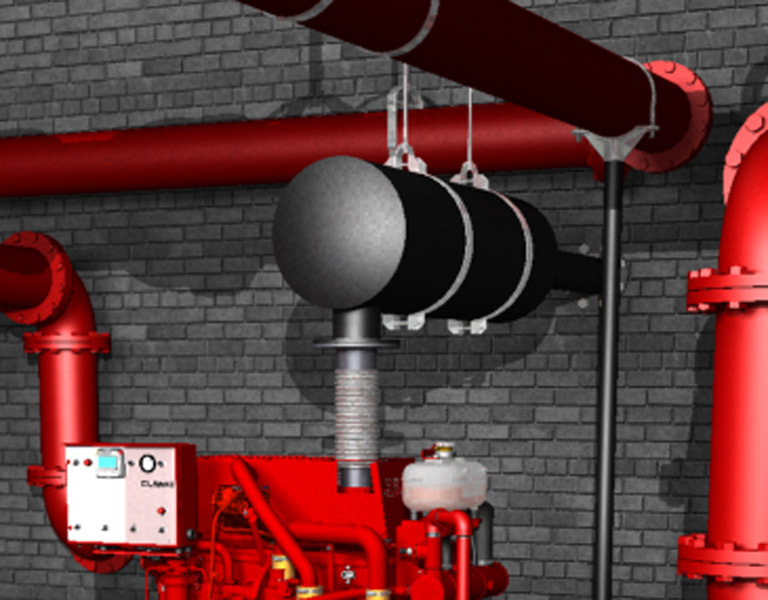

- Exhaust Backpressure – Confirm the silencer's backpressure for the selected Clarke engine will work with the exhaust system design (pipe size, elbows, straight pipe, silencer type).

- Pump Room Ventilation Sizing – Adequate pump room ventilation is critical, so you must determine the amount of airflow that is required for engine combustion and to remove the engine radiated heat.

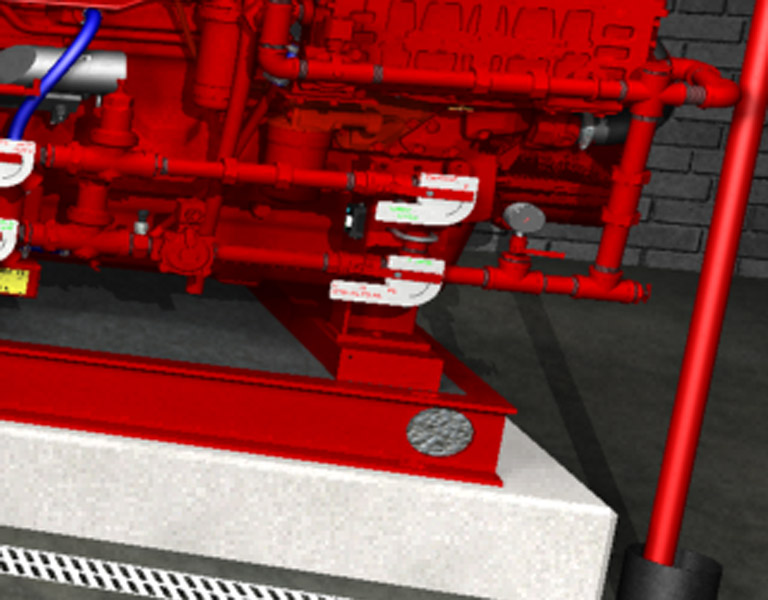

- Cooling Loop Sizing - Cooling Loops (also known as a bypass loops) allow for raw water to travel from the pump to the engine's heat exchanger to be used to remove the heat from the engine coolant. You must make sure the cooling loop is sized correctly for your fire pump room.

- Diesel Fuel Tank & Piping Sizing - Determine the correct diesel fire tank size and supply and return fuel line/pipe dimensions for your pump room.

- PLD-D Discharge - Protect against over and under discharge pressurizations by selecting a variable speed discharge pressure limiting control (PLD-D) certified diesel fire pump driver.

- PLD-S Suction - Protect suction supply piping by selecting a Clarke variable speed suction pressure limiting control (PLD-S) certified diesel fire pump driver.

- Water Temperature Rise – Calculate a Clarke engine's cooling water temperature based on the raw water supply inlet temperature, the raw water flow rate, and the heat produced with the engine running.

Find the Right Diesel Fire Pump Engine for Your Pump Room

Still have questions after utilizing our calculators? Our team is here to help. Contact Us today for assistance with your fire protection needs.